At 14:00 on October 23, 2020, the Tongji DIAN Racing Team’s "DIAN · Brave Winds and Waves" new car launch was officially held in the Porsche Experience Centre, Shanghai.

At 14:00 on October 23, 2020, the Tongji DIAN Racing Team’s "DIAN · Brave Winds and Waves" new car launch was officially held in the Porsche Experience Centre, Shanghai.TPM3D, Porsche, Schaeffler and other sponsors providing manufacturing support for the new models also attended this event.

>About DRe20

Boasting a series of technical upgrades, the DRe20 inherits the "lighter, faster, more stable" design concept of the DRe models. Concerning the lightweight design, the team has further optimized the carbon fiber layup and insert for themonocoque while guaranteeing the strength and reliability of parts, accompanied by the suspension and wheel-side system featuring a more sophisticated design. As a result, the team has further reduced the vehicle’s weight, while the carbon fiber rims have entered the testing phase and will soon be put into use, resulting from team’s independent R&D.

>TPM3D Delivered a Speech, illustrating how the applications of SLS technology can be incorporated into the manufacturing of racing cars.

NO.1

As the Tongji DIAN Racing Team produces the electric racing cars, TPM3D has offered nearly 100 types of auto parts produced by SLS printers, totaling 200 printed parts.

NO.2

The parts include battery modules, controller brackets, battery boxes, current sensors, instrument panels, body wings, front wings, tail wings, motor jackets, air ducts, rear shutters, rear ducts, steering wheels, etc.

NO.3

V0 flame-retardant nylon and PA12 materials have been put to good use for the manufacturing of parts inside the battery box, aerodynamic parts and heat dissipation parts.

>Technology sharing, advantages of TPM3D’s SLS technology for the manufacturing of racing cars

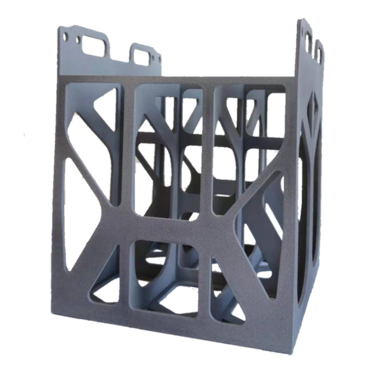

Typical parts - modular frame

Previous production process: fiberglass board bonding

Current production process: flame-retardant nylon SLS 3D printing

Advantages of TPM3D’s SLS printing:

> An overall frame weight reduction of 1000g.

> V0 flame-retardant nylon, safer performance.

> Sound protection for the cell, high accuracy.

Typical parts – aero keel

Previous production process: metal aluminum wire cutting, thread processing

Current production process: nylon SLS 3D printing

Advantages of TPM3D’s SLS printing:

> Weight of parts at the same locations is reduced by 15%, making it easier to design the complex connection structure.

> Good mechanical properties and sound fatigue resistance.

> Light weight, high machining accuracy.

Typical parts - motor jacket

Previous production process: resin 3D printing

Current production process:nylon + glassfiber SLS 3D printing

Advantages of TPM3D’s SLS printing:

> Enables the design and manufacturing of complex structures and parts.

> Light weight, high machining accuracy.

> Good mechanical properties and sound fatigue resistance.

Typical parts – battery box front cabin

Previous production process: fiberglass boards processed by CNC machining

Current production process: flame-retardant nylon SLS 3D printing

Advantages of TPM3D’s SLS printing:

> Weight of parts at the same locations reduced, making it easier to design the complex connection structure.

> V0 flame-retardant nylon, safer performance.

> High accuracy, good mechanical properties.

Sharing the actual case enabled the audience present to gain a more intuitive understanding of how SLS technology was applied in car manufacturing. For years, TPM3D's SLS printing technology has been widely applied to prototype design verification, interior and exterior decoration, steering wheels, seats, industrial controls, exterior decoration and tires, etc. Meanwhile, SLS printing technology has also witnessed a wide range of applications in medicine, electronic consumption, aerospace, and education. SLS printing technology is becoming more and more ubiquitous in our lives, in this way serving us.

During the launch, Porsche and Schaeffler also shared a wealth of information. As a co-sponsor of the manufacturing of a new DRe20 car, TPM3D hopes to join hands with Porsche and Schaeffler to wish Tongji DIAN Racing Team a better performance in the upcoming Formula Student China in 2020, thus securing a better ranking.