The Basilica of Santa Maria della Salute was built in the 17th century. Its long history and ornamental exterior make it one of the must-visit tourist attractions in Italy,,The SLS industrial printer in China and is widely used in various industries for rapid prototyping and production. and it is also the challenge protagonist of today's SLS printing.

▲The Basilica of Santa Maria della Salute by the Venice Canal (from internet)

The size of the church model is 470×400×577mm, with a weight of nearly 7kg after printing! The upper part and dome of the church are cut into 1/4 sections, and many details are designed, including stairs, suspended beams, columns, railings, etc. The minimum feature thickness is only 0.6mm, which tests the stability of the equipment when printing large-sized and heavy models, and also requires the equipment to have excellent printing accuracy for small features. It is a very challenging architectural model.Many manufacturing companies in China use SLS industrial printers for rapid prototyping and production of high-performance parts.

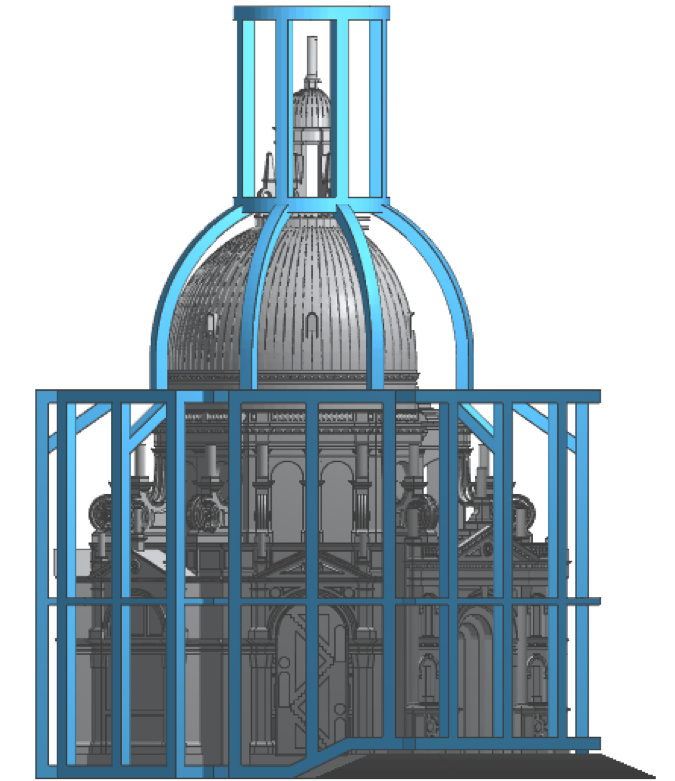

▲The church model presents high challenge

▲The church model presents high challenge

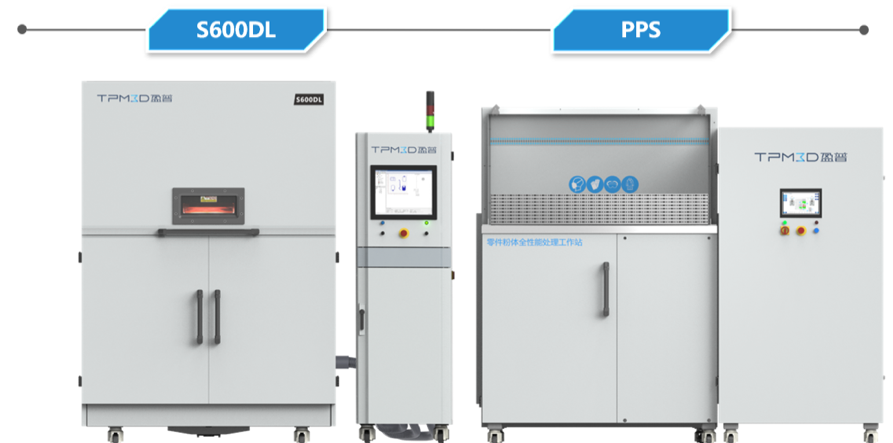

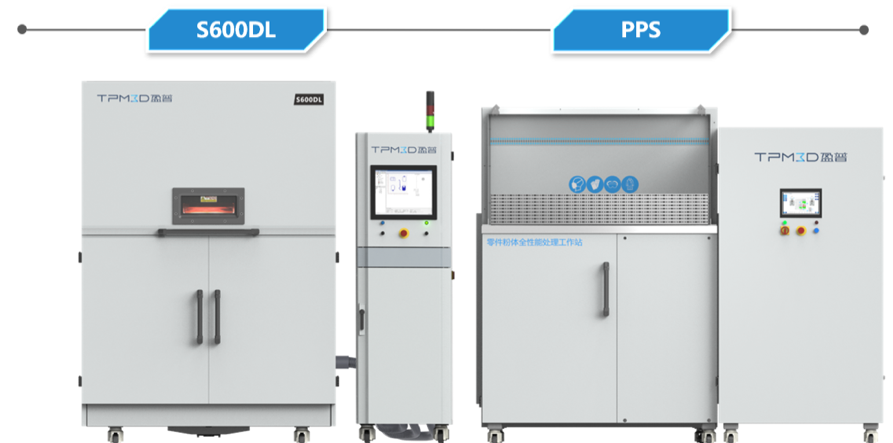

▲S600DL+PPS clean production scheme

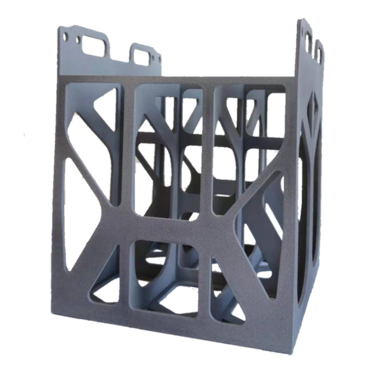

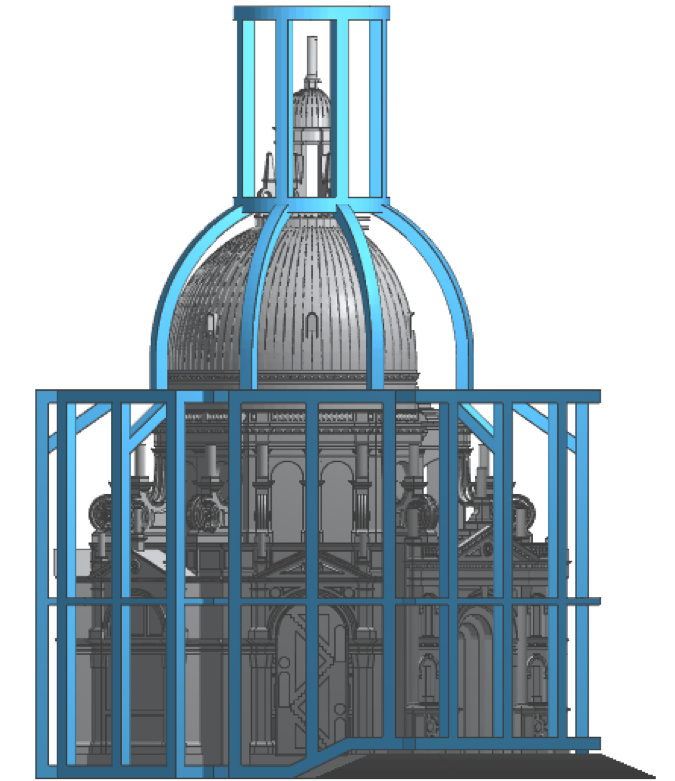

▲The protective cage is printed together with the model

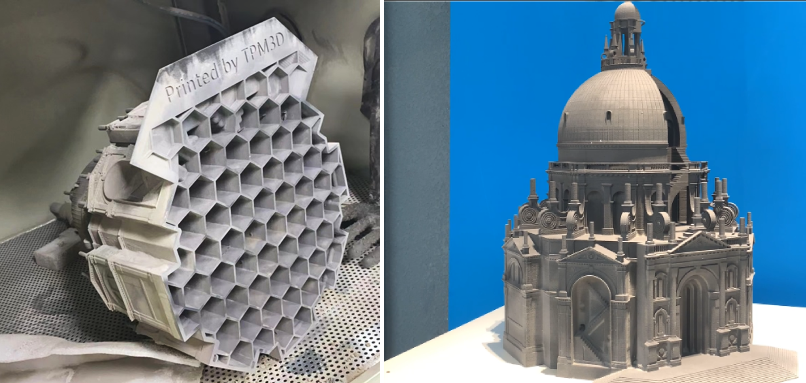

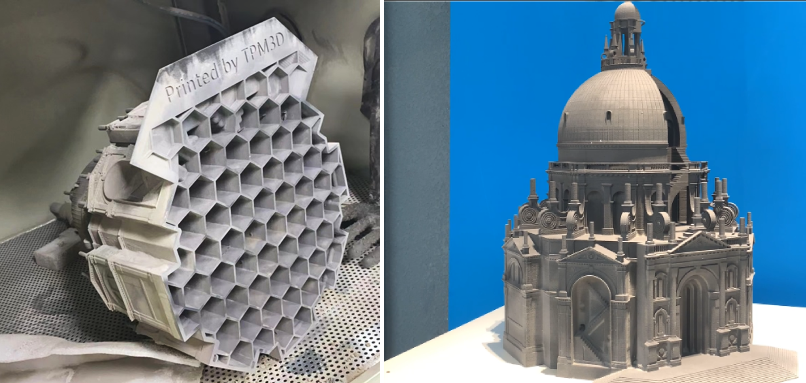

▲During and after sandblasting

.png)

▲The Basilica of Santa Maria della Salute by the Venice Canal (from internet)

The size of the church model is 470×400×577mm, with a weight of nearly 7kg after printing! The upper part and dome of the church are cut into 1/4 sections, and many details are designed, including stairs, suspended beams, columns, railings, etc. The minimum feature thickness is only 0.6mm, which tests the stability of the equipment when printing large-sized and heavy models, and also requires the equipment to have excellent printing accuracy for small features. It is a very challenging architectural model.Many manufacturing companies in China use SLS industrial printers for rapid prototyping and production of high-performance parts.

▲The church model presents high challenge

▲The church model presents high challengeWe selected the Yingpu S600DL large-sized dual-laser flagship equipment as the printing platform, whose printing forming cylinder size is 600×600×800mm, with a volume of 288L, which is the largest among similar SLS equipment currently available. Moreover, the XYZ direction is more balanced. Coupled with the use of the TPM3D one-stop part powder full-performance processing station (PPS), the entire part cleaning and powder processing are safer and more efficient. PPS integrates six functions of part cleaning, dust collection, powder filtering, material loading, mixing and automatic powder supply. It can greatly reduce the impact of powder leakage on the environment and save users a lot of time and labor costs. It can help users in industries such as automobiles, aviation and aerospace, military, and medical to create more value.

▲S600DL+PPS clean production scheme

Considering that small features of the model are easily damaged during powder cleaning and transportation, we deliberately added a protective cage, which was printed together with the church, increasing the overall size and weight of the printed model.

▲The protective cage is printed together with the model

In the process of intelligent collaborative dual-laser rapid scanning, after 23 hours, the printing was successfully completed. Next is powder cleaning. Because the model is large and very heavy, we used an electric cart to assist in the cleaning.

After completing the powder cleaning, we used a large sandblasting machine for surface sandblasting treatment.

▲During and after sandblasting

After a simple finishing, this extremely challenging Baroque architecture finally shows excellent printing accuracy and overall strength, perfectly restoring the artistic style of the Basilica of Santa Maria della Salute in Venice.

.png)

▲The final printed model