1.What is an SLS printer?

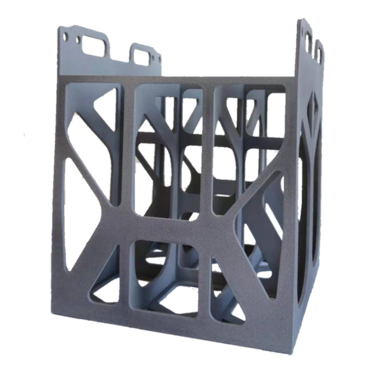

SLS 3D printer is a 3D printer that uses laser selective sintering rapid prototyping technology to print. It uses the laser as the energy source. Under the precise guidance of the computer-controlled optical path system, the laser beam scans at a certain speed and energy density according to the layered contour of the part on the processing plane where the thin layer of powder material is uniformly spread, and selectively Sintering, the sintering or melting of a powdered material and solidification to form a thin layer of a part. After the sintering of one layer is completed, the working platform is lowered by one layer thickness, and the new layer is re-sprayed and sintered. This cycle is repeated, layer by layer, and finally a three-dimensional solid part is obtained. SLS 3d printing technology is actually a zero waste technology, where the unsintered powder can be used over and over again for the next print.

2.What is better SLA or SLS?

First of all, the unsintered powder of SLS supports the cavity and cantilever part of the model during the molding process, and it is not necessary to generate a supporting process structure as in the SLA process.

Secondly, the materials printed by SLS are polymer materials, including PA, TPU, PP, PEEK and other materials, which have a wider range of applications. SLA usually uses photosensitive resin materials, and the application is relatively limited.

Finally, the surface of SLA-printed parts is smoother and the color is richer, but the toughness is not as good as that of SLS-printed parts, and the compression ability is stronger than that of SLA-printed parts.

3. Are SLS printers worth it?

Certainly. SLS printer is a zero-waste rapid prototyping technology among many 3D printers. It can print a variety of materials and has a wide range of applications. The printing process does not require support, the molding material has high reusability, and the complexity of the part structure is not limited. Although the surface accuracy of directly printed parts is somewhat insufficient, it can be combined with various post-processing processes.

4.How much is a SLS printer?

Different configurations have different prices, and desktop-level SLS printers usually have tens of thousands to hundreds of thousands. Industrial-grade SLS printers typically range in the hundreds of thousands to millions.

5.Is SLS printing strong?

The answer is undoubtedly yes! SLS printing technology is a zero-waste 3D printing technology. The printed powder materials can be reused, and the printing materials are diverse. The performance of the printed parts is excellent. It can be used for both prototype verification and end products. Consumer electronics, medical care, education, cultural and creative products, aerospace and other fields.

6.Is SLS 3D printing expensive?

The cost of SLS printing is falling as technology develops and materials diversify. From industrial R&D verification to personal end product use, the cost is getting lower and lower. It is for this reason that SLS printing is becoming more and more widely used.

SLS 3D printer is a 3D printer that uses laser selective sintering rapid prototyping technology to print. It uses the laser as the energy source. Under the precise guidance of the computer-controlled optical path system, the laser beam scans at a certain speed and energy density according to the layered contour of the part on the processing plane where the thin layer of powder material is uniformly spread, and selectively Sintering, the sintering or melting of a powdered material and solidification to form a thin layer of a part. After the sintering of one layer is completed, the working platform is lowered by one layer thickness, and the new layer is re-sprayed and sintered. This cycle is repeated, layer by layer, and finally a three-dimensional solid part is obtained. SLS 3d printing technology is actually a zero waste technology, where the unsintered powder can be used over and over again for the next print.

2.What is better SLA or SLS?

First of all, the unsintered powder of SLS supports the cavity and cantilever part of the model during the molding process, and it is not necessary to generate a supporting process structure as in the SLA process.

Secondly, the materials printed by SLS are polymer materials, including PA, TPU, PP, PEEK and other materials, which have a wider range of applications. SLA usually uses photosensitive resin materials, and the application is relatively limited.

Finally, the surface of SLA-printed parts is smoother and the color is richer, but the toughness is not as good as that of SLS-printed parts, and the compression ability is stronger than that of SLA-printed parts.

3. Are SLS printers worth it?

Certainly. SLS printer is a zero-waste rapid prototyping technology among many 3D printers. It can print a variety of materials and has a wide range of applications. The printing process does not require support, the molding material has high reusability, and the complexity of the part structure is not limited. Although the surface accuracy of directly printed parts is somewhat insufficient, it can be combined with various post-processing processes.

4.How much is a SLS printer?

Different configurations have different prices, and desktop-level SLS printers usually have tens of thousands to hundreds of thousands. Industrial-grade SLS printers typically range in the hundreds of thousands to millions.

5.Is SLS printing strong?

The answer is undoubtedly yes! SLS printing technology is a zero-waste 3D printing technology. The printed powder materials can be reused, and the printing materials are diverse. The performance of the printed parts is excellent. It can be used for both prototype verification and end products. Consumer electronics, medical care, education, cultural and creative products, aerospace and other fields.

6.Is SLS 3D printing expensive?

The cost of SLS printing is falling as technology develops and materials diversify. From industrial R&D verification to personal end product use, the cost is getting lower and lower. It is for this reason that SLS printing is becoming more and more widely used.