TPM 3D Asia Advanced Materials Printing Center

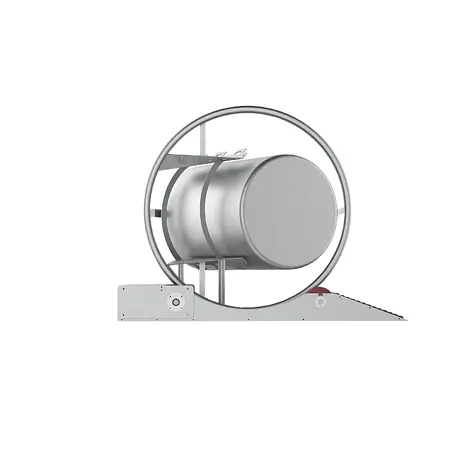

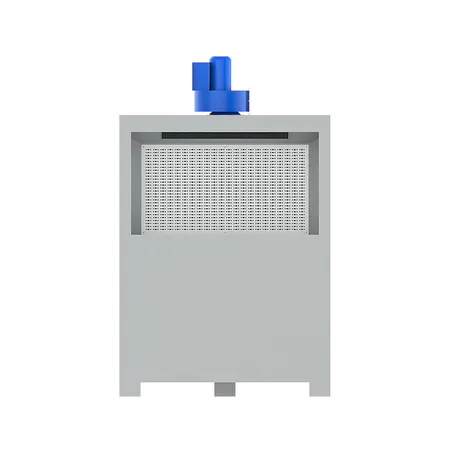

TPM 3D Asia advanced materials printing center located in Jiangsu Province, cover the area with more than 1000 m2. The center consists of intelligent manufacturing 3D printing display platform, industrial and advanced materials intelligent printing center, medical sterile R&D experiment labs, and SLS post processing center and multimedia conference zone.

3D Printing Digital Medical Center

The center construction includes three phases, we can provide orthopedic insoles, orthopedic pillows, scoliosis braces, knee orthoses, application of surgical guides for head, pelvis, spine and knee joints and 3D printing of braces, as well as orthopaedic standardized implant products development.

Our research

TPM3D has successfully developed 10+ laser sintering additive manufacturing systems, and more than 10 kinds of polymer powder printing material for high-quality parts manufacturing, has more than 30 national patents as well.

Related Products

More items about nylon powder

Nylon Powder

TPM3D technical team has been engaged in industrial 3D printing business since 1999 and has become the industry brand with 20 years focusing on 3D printing service。

TPM3D has various customers at home and abroad from the fields of automobile, electrical appliances, electronics, medicals, cultural & creative, education, aerospace, such as Guangzhou Automobile, Dongfeng Motor, Gree Group, LG Electronics, TTI, Fohan Service Bureau, Tongji University, Southern University of Science and Technology, University of Texas at Austin, and Massey University Auckland.

The Properties of Nylon Powder

Nylon powder has high mechanical strength, high softening point, heat resistance, low friction coefficient, wear resistance, self-lubrication, shock absorption and noise reduction, oil resistance, weak acid resistance, alkali resistance and general solvent resistance, good electrical insulation, self-extinguishing, non-toxic, odorless, good weather resistance, poor dyeing.

Advantages of Fiber Reinfocement Nylon Powder

The disadvantage of nylon powder is that it has high water absorption, which affects dimensional stability and electrical properties. Fiber reinforcement can reduce the water absorption rate of resin, so that it can work at high temperature and high humidity.

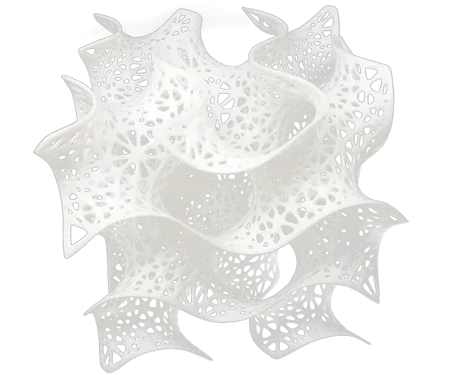

Nylon Powder | Wide variety and wide range of applications

Polyamide (PA), commonly known as nylon powder, is an engineering plastic with excellent performance, with excellent mechanical properties, outstanding corrosion resistance, oil resistance, heat resistance, high modulus and other advantages. In the 3d printing industry, PA12 and PA11 are used more, followed by PA6.

After the nylon material is reinforced and flame-retardant modified, its heat resistance, modulus dimensional stability and flame resistance can be significantly improved. At present, among the Precimid series printing powders of TPM3D, there are glass fiber reinforced nylon materials and carbon fiber reinforced materials. Nylon materials, including aluminum alloy reinforced nylon materials, as well as flame-retardant nylon materials, more than 30 kinds of SLS polymer powder printing materials are widely used in automobiles, electrical and electronic, power tools, consumer electronics, medical care, education, cultural and creative industries and aerospace. and other fields.

What is the Nature of Nylon Powder?

Nylon powder is composed of nylon resin powder and other substances in a certain formula ratio. It can make the coated surface more wear-resistant, rust-proof and chemical-resistant.

User Reviews

What users say about TPM 3D printing

Frequently Asked Question

Do you have any question?

PA12 AF nylon powder is a specialized variation of polyamide 12 (PA12) powder that incorporates added fillers, such as carbon fiber or glass fiber, to enhance its mechanical properties.

PA12 AF nylon powder offers improved strength, stiffness, and dimensional stability compared to regular PA12. It provides enhanced durability, wear resistance, and rigidity, making it suitable for demanding applications.

Industries such as automotive, aerospace, engineering, and manufacturing can benefit from PA12 AF nylon powder. It is ideal for producing robust and lightweight components that require superior strength and performance.

PA12 AF nylon powder is processed using selective laser sintering (SLS) technology. It is heated by a laser to fuse the powdered material layer by layer, forming complex three-dimensional objects with high precision.

Carbon fiber and glass fiber are commonly used fillers in PA12 AF nylon powder. These fillers improve the material's mechanical properties, enhancing strength and stiffness.

Depending on the desired outcome, post-processing steps such as surface finishing, dyeing, or coating can be performed to enhance the appearance and functionality of parts printed with PA12 AF nylon powder.

PA12 AF nylon powder is primarily used as a standalone material. However, it can potentially be combined with other compatible materials or additives to further enhance its properties or achieve specific requirements.

Future developments may focus on expanding the range of fillers available for PA12 AF nylon powder, optimizing the material's properties, and exploring new applications in various industries.